Made in Japan is cheaper than Made in China

Yamato industrial sewing machines are less expensive than Chinese-made machines because they are equipped with innovative devices that enable high-level performance for a quick return on investment. Interview of Mr. Shogo Kondo, President and CEO of Yamato Industrial Sewing Machine Mfg.Co.,Ltd, in "Newsweek" Febr,2021

|

We cannot reduce |

With garment factories today facing all kinds of severe competition globally, what garment manufacturers really want to know is howthey can produce garments both at low cost and high quality.

While many people compare sewing machine prices, Yamato focuses on reducing garment production costs to improve overall factory profitability by manufacturing superior-quality sewing machines. In fact, considering their high-quality performance, Yamatos sewing machines quickly pay for themselves and in effect are cheaper than standard Chinese-made machines. That is because while Yamatos Japanese-madesewing machines are more expensive than standard ones made in China, they significantly reduce garment production costs compared to Chinese-made machines.

Quick return on investment

We dont really consider other countries to be our competitors. Our products are superior in terms of return on investment, time to profitability, quality, durability, and longevity, says Yamato president, Shogo Kondo, who explains how the company’s flagship product can generate quick returns on invest-ment for garment manufacturers.

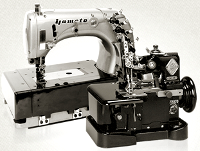

If a garment factory uses our EZH-B/UTQ model, which is our latest semi-automatic workstation with an under-thread trimmer with Stitch-Lock function, then the need for follow-up processes using a bar tack machine and its operator can be eliminated when factories and buyers collaborate. If you have two Yamato workstations per sew- ing line, and you have 10 sewing lines, then in 3-4 years, you can not only recoup your investment but also save enough money to buy a Mercedes-Benz car.

Quick start-up time in new locations

Once garment production has been shifted to a low-labor-cost country, it is difficult to find skilled sewing operators, resulting in lower productivity for the first several months and lower profits due to poor product quality.

Yamatos latest deskilling sewing machines solve that problem. With these machines, anyone can sew with even difficult-to-stitch fabric to create a beautiful finished product to high- quality international standards without special skills or extensive experience. Such innovations are the result of Yamatos efforts to continually create improvements that reduce its customers start-up costs and time to profitability.

Order-winning features - Only from Yamato

Many apparel companies have chosen Yamatos excellent -8 series because it raises their quality level and allows them to make competitive proposals, leading to the acquisition of new customers and more orders from existing customers.

Yamatos innovative engineering and product development capabilities have been highly regarded by leading garment manufacturers and their clients. Famous brands say that Yamato has the most professional engineers in the industry and that Yamato leads the industry in innovation. Made in Japan is the mark of good quality and our customers can rely on our machines for 15-20 years. To manufacture various machine models flexibly and with short production lead times, Yamato has used the Toyota Production System and the Toyota Management System since 1995.

With the Yamato Way of marketing and the use of Yamatos Production System as its core, Yamato has remained consistently profitable and financially robust, even when faced with major economic crises, such as those after the 9/11 attacks in 2001, the 2008 global financial crisis, the 2010 European debt crisis and the 2020 Covid-19 crisis. This is one of the reasons why Yamato always keeps growing despite intensified global competition.

No. 1 choice for leading garment makers

Major leading garment factories all over the world are using Yamato sewing machines as their primary equipment. The most successful companies Yamato has worked with from the beginning now rank among the top 10 large-scale garment factories in the world today. The largest have over 80,000 employees and around 60,000 machines each. All of these leading garment companies trust in the Made-in-Japan quality machinery offered by Yamato to ensure the quality of their own end-

user products.

Yamato is the best choice for customers who want to distinguish their products from their rivals, reduce costs and deliver the highest-quality products, leading to the acquisition of new, high-end customers and higher profits,” explains Mr. Kondo. Therefore, overall, garment factories have increased profits and savings, strengthening themselves financially year after year. Yamatos latest sewing machines are the best choice for garment factories to remain competitive.

In six years, Yamato will mark its 100th anniversary, which will serve as a fitting moment for the company to reflect on its proud history of high-quality, while also envisioning its future role as one of the industrys leading innovators.

We at Yamato are proud of the fact that everyone recognizes Yamatos brand as the highest quality in the industry, concludes Mr. Kondo. We always want to remain one step ahead as a reliable Solution Provider and innovation leader

serving the garment industry. We cannot reduce our machines prices, but we can reduce your T-shirt production costs. Made in Japan.

Model EZH-B/UTQ, semi-automatic workstation for hemming,

equipped with an automatic thread trimmer with anti-unravel function.

Source:

Newsweek International

19.02.2021

click here

Newsweek International

Yamato MG-2004P high speed 4 (2) needle cylinder bed, needle feed doublechain stitch machine for waistband manufacturing on jeans and work wear.The machine has optimum balance and high rigidity for heavy materials, with high speed performance. Feeding mechanism guarantees consistent stitches when sewing multi layer sections. Machine provides automatic lubrication and double roller puller system. Standard needle gauge available: 2-needle 31,8 mm; 2-needle 34,9 mm or 38,2 mm as 4- needle application.

Busche provides this work station with special waistband folder, photocell controlled waistband cutting system and new mechanism to switch off needle movement to skip number of stitches in the beginning or end of the waistbandsewing operation.

Please Experience the True “Automation” at YAMATO Booth 4-201 (Hall 4) !!! JIAM 2016 OSAKA Japan International Apparel Machinery & Textile Industry Trade Show. April 6 – 9, 2016 . At JIAM 2016 Osaka, we, Yamato will propose various solutions for the recent increasing demands for “Automation” in knitwear (Athletic Wear, Intimate Wear, T/Polo etc.) production, to secure your productivity and to standardize good quality, without relying so much on skillful hands, such as…

Please Experience the True “Automation” at YAMATO Booth 4-201 (Hall 4) !!! JIAM 2016 OSAKA Japan International Apparel Machinery & Textile Industry Trade Show. April 6 – 9, 2016 . At JIAM 2016 Osaka, we, Yamato will propose various solutions for the recent increasing demands for “Automation” in knitwear (Athletic Wear, Intimate Wear, T/Polo etc.) production, to secure your productivity and to standardize good quality, without relying so much on skillful hands, such as…

- Semi-automated workstations, designed to deskillize critical sewing operations and to improve finishing quality dramatically, without sacrificing productivity.

- Value-adding workstations for standardized finishing sizes, while saving material waste.

- Stress-free workstations to minimize downtime without requiring operators to pay so much attention.

- Superior fundamental function of machines to meet various sewing conditions. … and many more.

Also, Yamato will to show the high performance machines and saving packages for Tailored garments as well as jeans.

Examples of Solutions Yamato proposes:

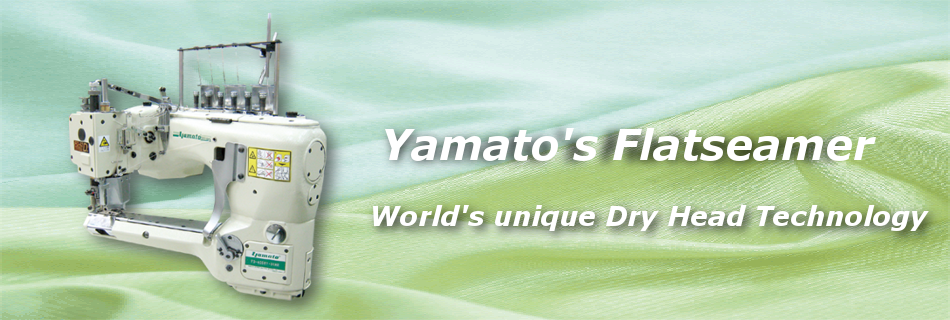

Twist-free flat hem, without skilled hands ?

Neat neckline, free from shape-off and puckering ?

Tacking can be eliminated, without risk for seam unravelling ?

200%+ seam elasticity to save you from consumer claims ?

Minimized risk for oil spots, as well as downtime and environmental impact???